-

Posts

26,273 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by mtaylor

-

Thanks for well wishes and comments but it really is only a flesh wound. Could have been more serious, but I got lucky this time. Hopefully there won't be a "next" time. Paul, This particular part is pear. Not swiss pear, but just plain pear. Paul and Grant, The bit is a Dremel router bit with a 1/8" shank. My mill spins it at about 12,000 rpm. Aldo, Glad you saw the clamps.. I wouldn't want you to think you'd need to be coming the States to stitch me up. I'm pressing on, a bit slower right now but still pressing on.

-

Beautiful Rusty. The bloodwood really is a wonderful touch.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

Gripos-kaiki by Giorgos - FINISHED

mtaylor replied to Giorgos's topic in - Build logs for subjects built 1851 - 1900

Amazingly fast and amazingly wonderful. Wow! -

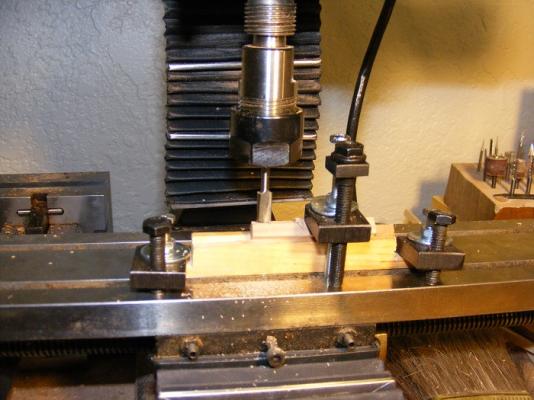

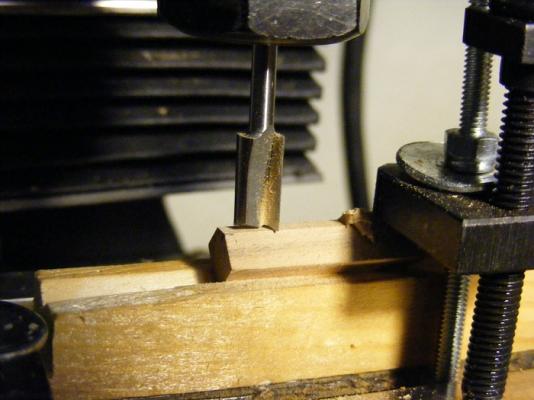

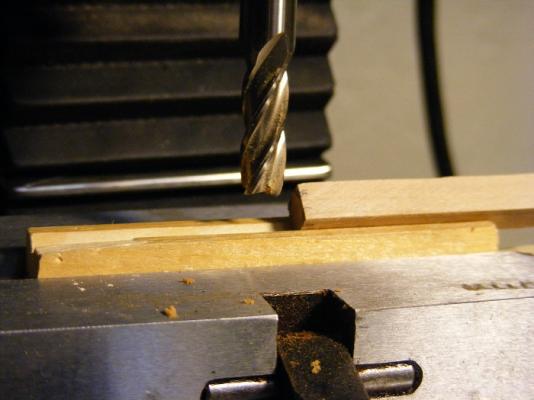

Here's the right and SAFE way to do it. And I'm wondering if this bad and then the correct way should be posted in the tools section as a reminder...??? The jig and workpiece are properly secured to the mill table using clamps. The cutting bit is run down to correct depth and bingo.... no movement, a perfect cut at the perfect width. Sidestory.. I'm debriding the wounds earlier and applying fresh bandages and my Admiral saw the mess and winced. A bit later she sees me working at this and says: "Nothing slows you down, does it?". My response was the usual "It's just a flesh wound". She looks at me and said: "No more Monty Python movies for you". This from the lady who after surgery is back lap swimming....

-

Thanks everyone. No permenant damage should result other than some messed up fingerprints. A hand plane has to be ordered as I suspected. Called several tool houses and the LHS. No handplanes of any size. So, I'll toss an order to Lee Valley after some research. Meantime, I'm reworking my jig to use clamps and holddowns to keep my tender bits away from that spinning cutter. The experiment and learning experience continues.....

-

Ah... not metal securing the lower deadeyes? Using line? If so, try 'painting' the line with PVA, or matte lacquer. What's happening is the tension causes the line to twist or unravel. It also works for the top deadeyes, thus, the recommendation for 'pre-tensioning' them to get rid of the twist before reeving the lanyard.

- 773 replies

-

- san francisco ii

- artesania latina

-

(and 1 more)

Tagged with:

-

Nice work on the stern Kevin. And a good catch on the chainplates. I guess the Inquisition didn't investigate any involvment by the wabbits for fear of retaliation?

- 1,319 replies

-

- caldercraft

- Victory

-

(and 1 more)

Tagged with:

-

Thanks for the encouraging words, everyone. The liquid anesthesia helped as did the realization that I was just being dumb. The damage is minimal and could have been worse. It really is my stupidity for not listening to the voice in my head saying: "Don't be an idiot.. ". I was taking a series of small cuts on each pass, just got caught by not thinking "what if?". I'm looking locally for a small hand plane but looks like an online order will be needed. <sigh> Meantime, I'll reconfigure the mill tonite and fiddle using clamps to secure everything. I still want to learn this tool and what it can do.

-

The deck is finally sanded but no finish has been applied. I'll hold until all the deck furniture and the aft area of the great cabin is completed. So on to some deck furniture.... I'll preface this with: DON'T TRY THIS!!!!!!!!!! I chose to do the pumps next. Octagonal in shape with a peculiar hourglass chunk of metal at the top of the pump rod. Rope is lashed around this, the runs up to a long bar lashed to the mast. The other end of the bar has a rope coming back down with 10 smaller ropes attached to it. Thus, as many as 10 men could be pulling down the rope and operating one pump. I presume in an emergency 20 men on the gun deck and 20 on the quarterdeck could get all 4 pumps working at the same time. Four pieces of pear were cut from stock... 1/4 inch (7 mm) by 1/4 inch (7mm) by 2" (51mm) each. I marked them appropriately. I then took a piece of fir and put an appropriate groove in it, mounted it squarely and securely in the vise on my mill. The pic shows the mounting along with one of the pear pieces. Here's where life gets interesting with one of those "what could I possibly be thinking" moments. I hand fed the pear through the mill on three sides and was feeling pretty good about the way things were going. Flipped for the 4th side and then.... the bit hit something.. small knot? Not sure and probably never will know. The wood was ripped from the jig and my fingers and sent flying into the ether. I've got two fingers on my right hand missing about 10 sq. mm of skin on each and a nasty cut on one finger of the hand. There's blood on the mill and bench. The pear piece is somewhere not to be found and my fingers are covered in bandages (plasters) and I'm asorbing liquid anesthetic from a brown bottle. So.... lesson learned. Don't hand feed. I'm reworking the scheme to clamp the wood for milling or I'm headed to the tool store tomorrow to find a halfway decent (hopefully a really decent) miniature plane.

-

How to install pedestal stands

mtaylor replied to LMDAVE's topic in Modeling tools and Workshop Equipment

Dave, Haul the sails slightly off center to port and tell folks who notice the lean that "she's carry plenty of sail and wind is a bit sharp".... Look great on the pedestals. For protection, wrap the entire base in Saran Wrap (or the plastic wrap of choice. Works a treat. -

Hmm... my monitor turned blue at that outburst... I will, from henceforth, when on your build or John's or anyone else's where it's deemed appropriate, use the "proper" English spelling of words as opposed to the 'Merikan way. I'll also be calling plexiglass... perspex. By the way.. would you prefer Imperial or Metric or perhaps some obscure measuring units.. just and 100th's of a furlong? The things we do to keep everyone happy... sheeeshhhh.....

- 1,148 replies

-

Sjors, You were missed. It's good to hear you are back home safe and sound. Also it's good to hear that London's buses are still in London. So when do we see some pictures of your Le Mirage??? Just kidding the ship pictures. I know you are busy.

-

Endeavour Model at the Powerhouse Museum

mtaylor replied to Jim Lad's topic in Nautical/Naval History

Seems a shame that these ships are in storage and unprotected. Thanks for the pictures John. -

Echo by Maury S - FINISHED - Cross-Section

mtaylor replied to Maury S's topic in - Build logs for subjects built 1751 - 1800

Sweet looking shot locker, Maury. The hardware is perfect.- 324 replies

-

JP, That might explain the missing masts on the Vic....

- 1,668 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Minty mast? Sounds like something one would stick in a drink with an umbrella in it. You could hang onto it as it would make a nice swizzle stick for hot chocolate. As for all the sesquipedalians popping up in untoward places such as this one and running amok, I must take due pause and go find the popcorn machine and the adult beverage dispenser before the verbage re-commences. On the other hand, I won't ask for more pictures and less barffelgab like certain others who are overdue in their appearance on these august pages. <ducks><run><dives for the bunker>

- 1,148 replies

-

Good to see you back at the worktable, Kats. The stanchions and scratch rail look super.

- 237 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Is this your first model? Just curious. Yes, it can be intimidating, but take your time, use the buildlog to get help and advice and have some fun along the way. When you're done, you have something to be proud of and to honor the late builder. BTW, filler is ok. Just don't use putty. The filler putties never harden.

- 23 replies

-

- renown

- billing boats

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.