Supplies of the Ship Modeler's Handbook are running out. Get your copy NOW before they are gone! Click on photo to order.

×

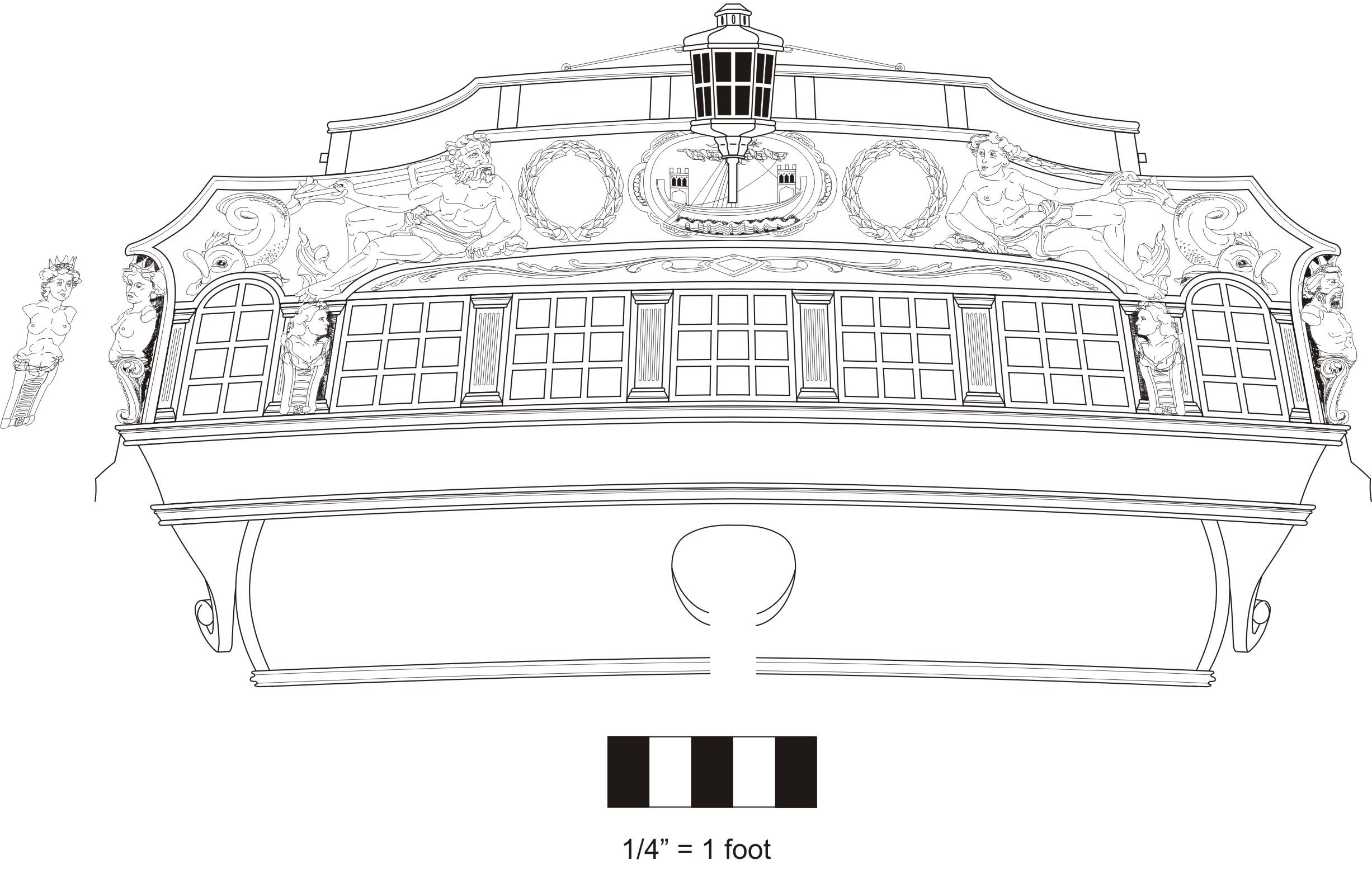

Group Prototype HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

Recently Browsing 0 members

- No registered users viewing this page.

Recommended Posts